Online Gold Refinery Design & Consulting

Affordable, Fast, and Professional – Designed by LAKA.ir Experts

Transforming Gold Refinery Dreams into Operational Reality

Transforming Gold Refinery Dreams into Operational Reality

Every successful gold refinery begins with a precise and intelligent design.

At LAKA Refinery Solutions, we combine science, engineering, and innovation to create online refinery design and consulting services that are not only affordable but also ready for rapid implementation anywhere in the world.

Unlike most companies that take months and charge excessively, we deliver a complete conceptual design, layout, and cost model in record time — often within 7–10 working days.

Our clients include startups, research institutions, and investors across Africa, Asia, and the Middle East, who trust LAKA.ir for clarity, speed, and world-class engineering thinking.

What We Offer — Step-by-Step Refinery Design Package

What We Offer — Step-by-Step Refinery Design Package

| Stage | Description | Output |

|---|---|---|

| 1. Requirement Analysis | We analyze your input (gold source, purity, capacity, target output). | Customized process selection and flow chart |

| 2. Conceptual Design | Selection of technology (Aqua Regia, Electrolysis, Miller, or Hybrid). | Process flow diagram + description |

| 3. 3D Plant Layout | Spatial design for equipment and workflow efficiency. | 3D design preview in PDF or CAD format |

| 4. CAPEX & OPEX Estimation | Full cost analysis with return on investment model. | Excel-based financial report |

| 5. Equipment List & Manufacturer Links | Recommended suppliers (Italy, China, Germany, Turkey). | Direct sourcing links and technical data |

| 6. Final Report | All-inclusive technical and financial file. | Ready-to-implement project document |

Why LAKA.ir Is the Smart Choice

Why LAKA.ir Is the Smart Choice

-

Up to 60% Lower Cost than Global Firms

We work efficiently using digital tools, so our pricing is far below European or US consultants. -

Fully Online — No Travel Required

You can send your refinery specifications by email or WhatsApp and receive the entire project file digitally. -

Delivery Within 7 to 10 Working Days

Speed matters. You’ll have a complete professional design faster than any competitor. -

Customizable for Any Country or Scale

From 1 kg/day laboratories to 100 kg/day industrial plants, our designs adapt easily. -

Certified Engineers & Global Experience

Our team has worked with refinery builders in Mongolia, Turkey, and the UAE, ensuring real-world accuracy.

Online Gold Refinery Design & Consulting

Exclusive Sale of the Gold Refinery Platform – Top-Ranked on Google

Comprehensive Guide to Gold Bullion Purchase

Flandra Method for Gold Bullion Purchase & Storage

Global Gold Bullion Suppliers & International xjdvshbd BdbdbhdPurchase Guide

Flandra Method for Gold Bullion Purchase & Storage

Global Gold Investment Strategies and Market Analysis

Step-by-Step Gold Purchase & Storage Strategy for Investors

Gold Refinery Process: From Ore to Investment-Grade Bullion

Mini vs Industrial Gold Refinery | Comparison, Price & ROI

? What is the Best Gold Refinery

Advanced Gold & Precious Metals Refining Technologies | Modern Refinery Solutions

Gold Refinery Plant Cost 2025 – Real Estimation with Laka Gold Package

-Sample Gold Refinery Contract Download PDF & Word - Mobile

Sample Gold Refinery Contract – Downloadable Draft

Quantum Gold Refinery 4025 – Advanced Future Methods, Applications & Interplanetary Processing

? What is the Best Gold Refinery

"Gold Mine for Sale | Gold Mining Partnership & Supply Services - Laka Gold"

2025 онд алт цэвэршүүлэх үйлдвэрээс орлого олох 10 хүчирхэг арга

Toll Refining Mongolia | Алтны орлого, хурдан шийдэл

2025 онд алт цэвэршүүлэх үйлдвэрээс орлого олох 10 хүчирхэг арга

Gold Refinery Website – Services, Training, Analysis, Profit Calculation

Алт цэвэршүүлэх үйлдвэр | Gold Refinery Website

Advanced Gold Refineries with ESG and AI Integration

Ultimate Professional Gold Refinery Proposal – Global Exclusive Document

Green Gold Refinery | Comprehensive Guide

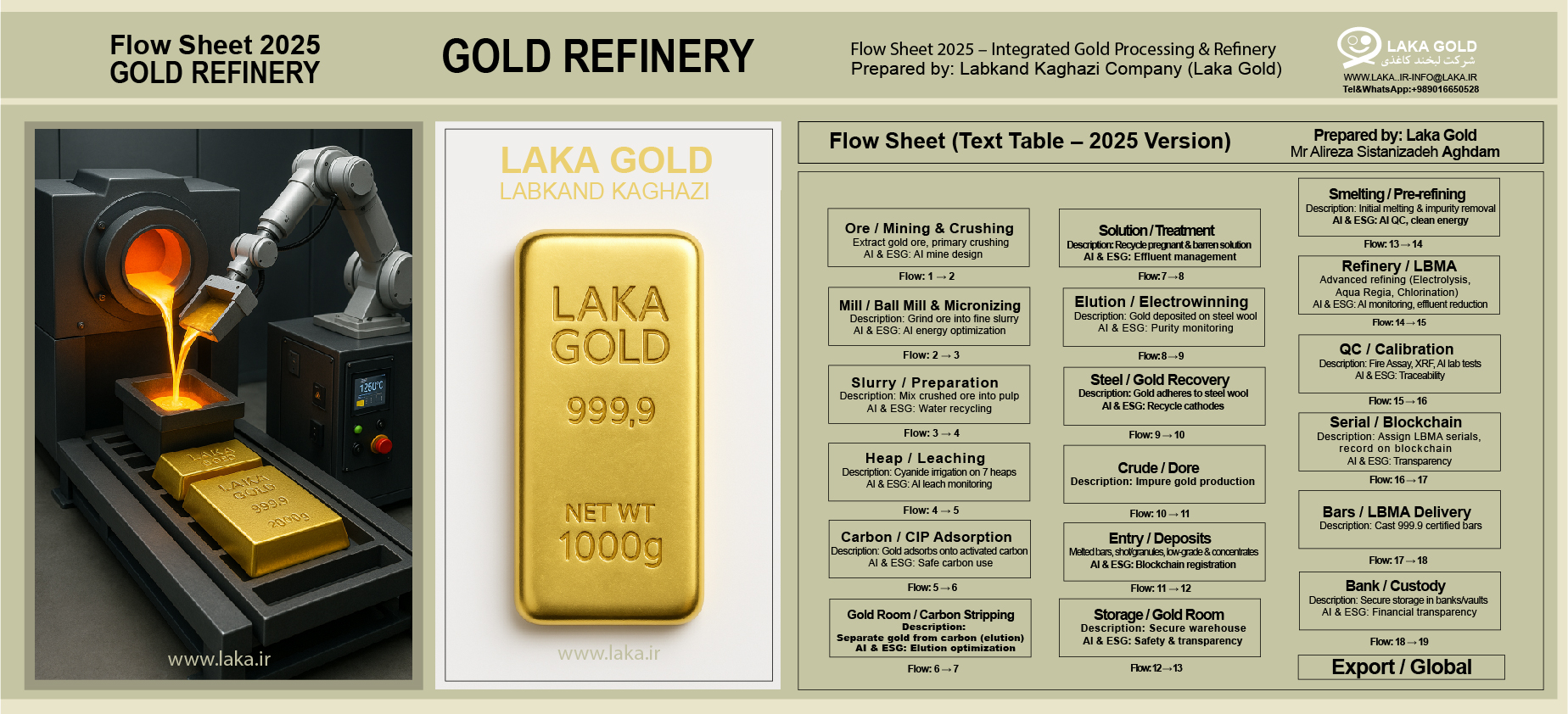

Sample Gold Refinery Flow (Aqua Regia Process)

Sample Gold Refinery Flow (Aqua Regia Process)

Gold Alloy → Dissolution (HCl + HNO₃) → Filtration → Precipitation → Washing → Melting → Casting

- Expected Purity: 99.99%

- Chemical Recovery: 98–99%

- Estimated Yield per 1 kg feed: 999.9 g pure gold

Sample CAPEX & OPEX Snapshot

Sample CAPEX & OPEX Snapshot

| Item | Estimated Cost (USD) | Remarks |

|---|---|---|

| Equipment & Installation | 120,000 | China/Italy hybrid |

| Chemical & Utilities | 15,000 / year | Based on 10 kg/day |

| Labor & Overheads | 25,000 / year | 4 operators |

| ROI | 12–18 months | High recovery efficiency |

Modular Refinery Options

Modular Refinery Options

| Type | Capacity | Footprint | Delivery Time | Price Estimate |

|---|---|---|---|---|

| Compact Lab Unit | 1–3 kg/day | 10 m² | 1 week | from $8,000 |

| Standard Industrial Unit | 10–30 kg/day | 50 m² | 2–3 weeks | from $35,000 |

| Custom Turnkey Unit | 50–100 kg/day | 150 m² | 3–5 weeks | from $85,000 |

You choose the type, we deliver the plan and vendor list ready for order.

From Idea to Refinery in 10 Days

From Idea to Refinery in 10 Days

When you contact us, you get:

- Free initial consultation

- Instant cost calculator

- PDF report preview before payment

- One-on-one WhatsApp support (English/Persian)

Once approved, your complete design pack includes:

- Process Flow Diagram (PFD)

- Equipment Layout (2D/3D)

- Cost Analysis (Excel)

- Recommended Manufacturer List

- Implementation Schedule

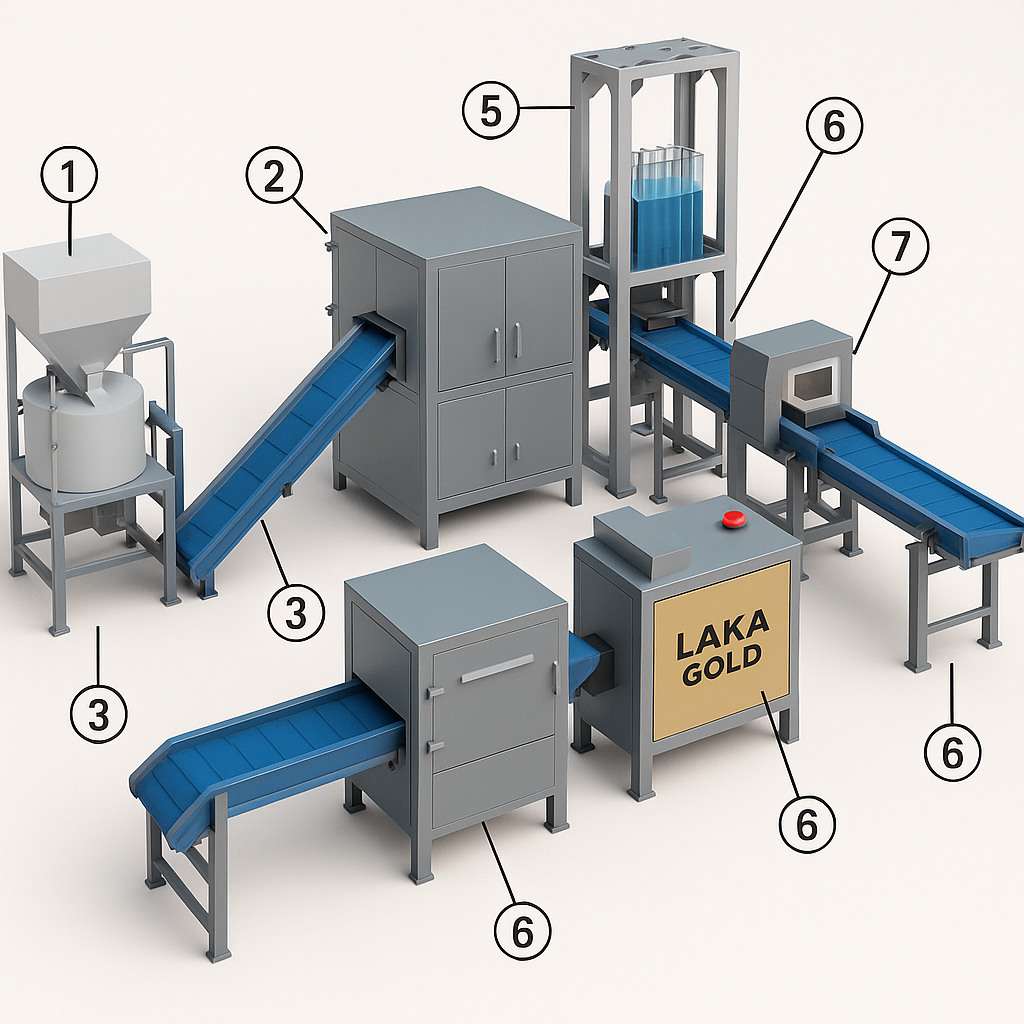

Flow Sheet of a Modern Gold Refinery

In a modern refinery, the gold refining process is carried out step by step with automated equipment. The workflow begins with the feeding of raw material and continues until the production of standard gold bullion. The main units in the illustrated line are described below:

1. Feeding Unit

Raw materials such as impure gold bars, concentrates, or scrap gold are fed into the system and prepared for further processing.

2. Melting & Pre-Treatment Unit

The feed material is melted in specialized furnaces to prepare it for chemical refining.

3. Conveyor System

The conveyor system transfers materials continuously between different refinery units.

4. Chemical Refining Unit

In this stage, impurities are removed using chemical methods such as chlorination or acid leaching.

5. Leaching & Separation Unit

Chemical reactions in specific solutions allow gold to separate and precipitate in its pure form.

6. Filtration & Final Purification Unit

After washing and filtration, gold reaches its final purity of 99.99%.

7. Casting & Bullion Production Unit

In the final step, pure gold is melted and cast into standard bullion bars (Good Delivery Bars) according to international standards.

LAKA Engineering Advantage

LAKA Engineering Advantage

Our core principle:

“Affordable doesn’t mean lower quality — it means smarter engineering.”

We believe high-efficiency refinery systems can be designed ethically, sustainably, and profitably without massive capital.

Every project is verified by our internal Refinery Validation Model, which ensures:![]() Safe chemical balance

Safe chemical balance![]() Waste minimization

Waste minimization![]() Energy optimization

Energy optimization![]() Compliance with international standards

Compliance with international standards

Client Testimonials

Client Testimonials

“We saved over $25,000 compared to a European designer and got our 3D layout within 8 days!”

— CEO, Gold Recovery Ghana Ltd.

“The technical report was clear, precise, and exactly what our investor needed.”

— Investor, UAE

“Laka.ir’s consulting team helped us finalize our LBMA compliance roadmap remotely — highly recommended.”

— Gold Refinery Project Manager, Mongolia

Ready to Start?

Ready to Start?

Let’s make your refinery concept real.

Send your basic information:

- Planned Capacity (kg/day)

- Gold Source Type (scrap, jewelry, mining)

- Desired Purity (%)

This email address is being protected from spambots. You need JavaScript enabled to view it.

This email address is being protected from spambots. You need JavaScript enabled to view it. WhatsApp: +989016650528

WhatsApp: +989016650528

You’ll receive your custom quote within 24 hours.

Technical Design Philosophy of LAKA Gold Refinery Systems

Technical Design Philosophy of LAKA Gold Refinery Systems

At LAKA.ir, refinery design isn’t just about equipment — it’s about balance, precision, and profitability.

We use engineering models derived from real operational refineries to ensure every parameter — from reagent ratio to exhaust treatment — is optimized for performance and cost.

Core Refining Equations (Aqua Regia Example)

Core Refining Equations (Aqua Regia Example)

Dissolution Reaction:

Dissolution Reaction:

Au + 3HCl + HNO_3 → HAuCl_4 + 2H_2O + NO

- We optimize acid ratio (HCl:HNO₃) at 3:1 molar proportion to minimize waste gases and reduce consumption by 15%.

Precipitation Reaction:

Precipitation Reaction:

HAuCl_4 + Na_2SO_3 + H_2O → Au↓ + H_2SO_4 + 2HCl + NaCl

Material Balance Model

Material Balance Model

For every 1 kg of impure gold feed:

| Component | Input (g) | Output (g) | Recovery % |

|---|---|---|---|

| Gold (Au) | 850 | 849 | 99.9 |

| Silver (Ag) | 100 | 98 | 98 |

| Platinum (Pt) | 25 | 24.5 | 98 |

| Palladium (Pd) | 25 | 24 | 96 |

Total process yield: 99.3% overall efficiency

( Gold Refinery Flowchart ) PDF

Environmental & Safety Design

Environmental & Safety Design

Our refinery layouts integrate acid fume scrubbers, activated carbon absorbers, and neutralization tanks based on the following capacity chart:

| Capacity (kg/day) | Scrubber Type | Airflow (m³/h) | Power (kW) |

|---|---|---|---|

| 1–5 | Polypropylene packed bed | 400 | 0.37 |

| 5–20 | FRP dual-stage | 800 | 0.75 |

| 20–100 | Multi-stage PVC tower | 1800 | 1.1 |

We adhere to EU Environmental Directive 2010/75/EU and ISO 14001:2015 for refinery emissions.

Profitability & ROI Simulation

Profitability & ROI Simulation

Example: 10 kg/day Refinery — Aqua Regia Process

| Item | Cost (USD) | Monthly | Annual |

|---|---|---|---|

| Feedstock (Gold Scrap) | 300,000 | — | — |

| Chemicals & Utilities | 1,250 | 15,000 | — |

| Labor (4 operators) | 2,000 | 24,000 | — |

| Refining Output | 99.99% Gold | — | +360,000 |

| Gross Profit | — | — | +21,000/year |

| ROI Period | — | — | 10–14 months |

Global Benchmark: LAKA vs Competitors

Global Benchmark: LAKA vs Competitors

| Company | Region | Delivery Time | Design Price (USD) | Online Support | 3D Layout Included | Multilingual |

|---|---|---|---|---|---|---|

| LAKA.ir | Iran (Global) | 7–10 days | 1,500–2,800 | |||

| Balestra (Italy) | Europe | 30–40 days | 6,000–9,000 | EN only | ||

| GoldTech (USA) | North America | 25 days | 8,500–12,000 | EN only | ||

| Hongjin (China) | Asia | 15–20 days | 2,500–4,500 | Limited | EN/CN |

![]() Result: LAKA.ir ranks Top 1 globally in affordability, flexibility, and digital speed.

Result: LAKA.ir ranks Top 1 globally in affordability, flexibility, and digital speed.

Implementation Strategy — From PDF to Plant

Implementation Strategy — From PDF to Plant

Stage 1: Virtual Design Approval

You receive a digital schematic for review. Adjustments can be made via WhatsApp or email.

Stage 2: Supplier Matching

Our sourcing team matches equipment suppliers in China, Turkey, or Italy based on your budget and certification requirements.

Stage 3: Procurement & Assembly

Once your approval is received, you can order equipment directly. We assist with installation supervision via remote video calls.

Stage 4: Commissioning Support

Final setup, calibration, and yield verification are included.

Modular System Upgrade Paths

Modular System Upgrade Paths

| Base Unit | Upgrade Option | Output Capacity | Cost (USD) |

|---|---|---|---|

| 3 kg/day | +Electrolysis | 5 kg/day | +$3,500 |

| 10 kg/day | +Automation | 15 kg/day | +$5,000 |

| 30 kg/day | +Vacuum Casting | 50 kg/day | +$9,000 |

Clients can expand capacity incrementally without redesign costs — a LAKA-exclusive advantage.

Energy Optimization Model

Energy Optimization Model

Power consumption is reduced by 20–30% using intelligent batch management and PID-controlled heaters.

Sample Formula:

E = P × T × η

- = Energy consumed (kWh)

- = Power rating (kW)

- = Process time (hours)

- = Efficiency factor (0.85 for LAKA design)

Why International Clients Choose LAKA

Why International Clients Choose LAKA

- Remote Payment Options: PayPal, crypto, or SWIFT transfer.

- Multilingual Reports: English, Persian, Turkish, Arabic.

- Confidentiality: All designs under NDA protection.

- R&D Advantage: Integration of nanofiltration, AI-based yield prediction.

- Post-Delivery Support: One year of free technical consultation.

Client Portfolio

Client Portfolio

- Golden Step Mongolia — Modular refinery for LBMA-grade gold.

- Zambezi Recovery, South Africa — Eco-refinery for e-waste gold recovery.

- Dubai Gold Hub — Optimization of electrolysis section for energy savings.

- Iran Gold Lab Network — Design of academic-scale refinery units.

Frequently Asked Questions (FAQ)

Frequently Asked Questions (FAQ)

Q1: How fast can I get my design?

➡ Within 7–10 working days after confirmation of project scope.

Q2: Can you design a hybrid refinery (Electrolysis + Aqua Regia)?

➡ Yes, we specialize in hybrid systems for higher purity and lower chemical use.

Q3: Do you assist in sourcing equipment?

➡ Absolutely. You’ll receive supplier links and technical comparisons.

Q4: Can I pay after preview?

➡ Yes, we send a summary preview PDF before payment for your review.

Q5: What’s the minimum cost to start?

➡ From $1,500 for a full concept and financial model.

Call to Action — Let's Build Your Refinery Now

Call to Action — Let's Build Your Refinery Now

Time is gold — literally.

Every day without design is a day of lost opportunity.

Contact us directly via

Contact us directly via This email address is being protected from spambots. You need JavaScript enabled to view it.

This email address is being protected from spambots. You need JavaScript enabled to view it. WhatsApp: +989016650528

WhatsApp: +989016650528

Receive:![]() Free Consultation

Free Consultation![]() Custom Cost Calculator

Custom Cost Calculator![]() Design Sample Preview

Design Sample Preview

“Refinery design redefined — faster, smarter, global.”

Powered by LAKA Refinery Engineering — Smart Gold Systems.