Gold Refining Process Overview

Introduction

Gold refining is an essential process that purifies gold extracted from ores, achieving a high level of purity suitable for industrial use, jewelry, and investment purposes. The refining process involves various stages, including extraction, separation, and purification, using both chemical and physical methods. This page provides a comprehensive guide to understanding the gold refining process, covering the different techniques, equipment, and stages of operation.

The goal of gold refining is to remove impurities from raw gold, often called dore bars, to achieve gold that is over 99.5% pure. This is achieved using various refining processes, each suitable for different types of gold ores and refining scales.

1. The Gold Refining Process: Step-by-Step Overview

Gold refining is not a simple process and involves several steps to remove impurities from the raw ore. Each step is essential to ensuring the gold reaches its highest purity level.

Step 1: Extraction of Gold Ore

The first step in the refining process is the extraction of gold from its natural ores. Gold is commonly extracted from rock, gravel, and alluvial deposits through two primary methods:

- Open-pit mining – This involves the removal of surface soil and rocks to expose the underlying gold-bearing ore.

- Underground mining – Gold ore is extracted from deep within the earth using shaft mines or tunnels.

Once extracted, the gold ore is then processed further to separate the gold from other minerals.

Step 2: Crushing and Grinding

Once the gold-bearing ore is extracted, it is crushed into smaller pieces to increase the surface area for further processing. This is typically done using crushers and mills.

- Crushing breaks the ore into smaller pieces, and then grinding further reduces the ore to a fine powder.

- The finely ground ore is then mixed with water and chemicals to extract the gold.

Step 3: Leaching Process (Cyanidation)

The most commonly used method for extracting gold from ore is cyanidation or cyanide leaching. In this process, the crushed ore is mixed with a cyanide solution, which dissolves the gold into a water-soluble complex.

- The cyanide reacts with the gold, forming a gold cyanide complex, which is then separated from the rest of the material.

- This method is particularly effective for gold ores that have low concentrations of gold or ores that are finely ground.

Step 4: Separation and Recovery

Once the gold is dissolved in the cyanide solution, the next step is to recover it. This can be done through several methods:

- Activated Carbon Adsorption – The gold-cyanide complex is absorbed onto activated carbon, which is then removed from the solution.

- Zinc Precipitation – Zinc dust is added to the solution, which causes the gold to precipitate out of the solution.

- Electrowinning – An electrochemical process that uses electricity to deposit gold onto electrodes, typically in the form of a pure gold plate.

Step 5: Smelting the Gold

The next step is to smelt the recovered gold into solid form. This is done by heating the gold concentrate at high temperatures in a smelting furnace.

- The gold is melted and separated from other impurities such as lead, silver, and copper.

- Fluxes are often added to help remove impurities, and the resulting product is a dore bar containing gold, silver, and other metals.

Step 6: Refining the Gold

The final step is the refining process, where the dore bar is purified to remove all remaining impurities. There are several methods of refining gold, each with its own advantages and disadvantages. Some of the most common methods are:

- Electrolytic Refining (Electrorefining): In this method, gold is dissolved and then re-deposited onto a cathode, producing very pure gold.

- Parting (Aqua Regia Process): This is a chemical process in which gold is dissolved in aqua regia (a mixture of hydrochloric and nitric acid) and then separated from other metals.

- Miller Process: This is a quick method for producing gold with a purity of around 99.5%. Chlorine gas is passed through molten gold to remove impurities.

2. Types of Gold Refining Processes

Gold refining can be done using several different techniques, each suited for different circumstances and types of gold ores. These processes can be divided into chemical, electrochemical, and physical methods.

2.1 Chemical Gold Refining Processes

Chemical processes are widely used because of their ability to produce gold of extremely high purity. Some common chemical processes include:

- Cyanidation (Leaching): As described earlier, cyanidation is used for extracting gold from ores by using a cyanide solution.

- Aqua Regia Process: A highly effective method for refining gold to a very high level of purity, typically used in laboratory settings.

- Miller Process: This is a simpler, less expensive method that uses chlorine gas to purify gold.

2.2 Electrochemical Gold Refining

Electrorefining or electrolytic refining is one of the most common methods used for refining gold in larger operations. This process is environmentally friendly and produces gold with 99.99% purity.

- The gold is dissolved in a gold chloride solution and then deposited onto a cathode through an electric current.

- This process is preferred in industrial gold refining.

2.3 Physical Gold Refining

Physical methods are typically used in small-scale operations and laboratories for their simplicity and cost-effectiveness. These methods include:

- Gravity Separation: Uses gravity to separate gold from other materials.

- Magnetic Separation: Uses magnets to separate magnetic impurities from gold.

- Flotation: This method involves adding chemicals to a slurry, causing gold particles to float to the surface for collection.

3. Common Challenges in Gold Refining

While gold refining can be highly profitable, it also presents numerous challenges, including environmental concerns, safety risks, and technological hurdles. Here are some of the main challenges faced in gold refining:

- Environmental Impact: Cyanide and other chemicals used in the refining process can be hazardous if not properly handled.

- Energy Consumption: The smelting and electrolytic processes require significant amounts of energy, making the process expensive.

- Waste Disposal: Proper disposal of waste products, such as cyanide sludge and other chemicals, is critical for environmental safety.

Conclusion of

The refining process for gold is a complex and highly technical procedure that requires specialized knowledge, advanced equipment, and significant investment. From extraction to smelting and refining, each step is crucial to ensuring that gold is purified to the desired level of purity. In the next part, we will delve deeper into the specifics of setting up a gold refining plant, including equipment procurement, plant layout, and regulatory requirements.

Top 10 Gold Refineries & Emerging Players Worldwide

Gold Refinery Turnkey Platform

Modular Gold Refinery Platforms | Turnkey Gold Refinery Systems by LAKA.ir

Gold Refinery Feasibility Study & Cost Estimation

Turnkey Modular Gold Refinery Platform – Ready-to-Install

Small-Scale Green Gold Refinery Solutions

Gold Refining Equipment Supplier Directory

Online Gold Refinery Design & Consulting -LAKA GOLD

Gold Refinery Process: From Ore to Investment-Grade Bullion

-Sample Gold Refinery Contract Download PDF & Word - Mobile

Sample Gold Refinery Contract – Downloadable Draft

Quantum Gold Refinery 4025 – Advanced Future Methods, Applications & Interplanetary Processing

Gold Refinery Plant Cost 2025 – Real Estimation with Laka Gold Package

Advanced Gold & Precious Metals Refining Technologies | Modern Refinery Solutions

? What is the Best Gold Refinery

بهترین ریفاینری طلا | What is the Best Gold Refinery

? What is the Best Gold Refinery

Mini vs Industrial Gold Refinery | Comparison, Price & ROI

ریفاینری شمش طلا | Gold Bullion Refinery

Global Sample Mini Gold Refinery | Compact, Scientific & Economical Gold Refining Unit

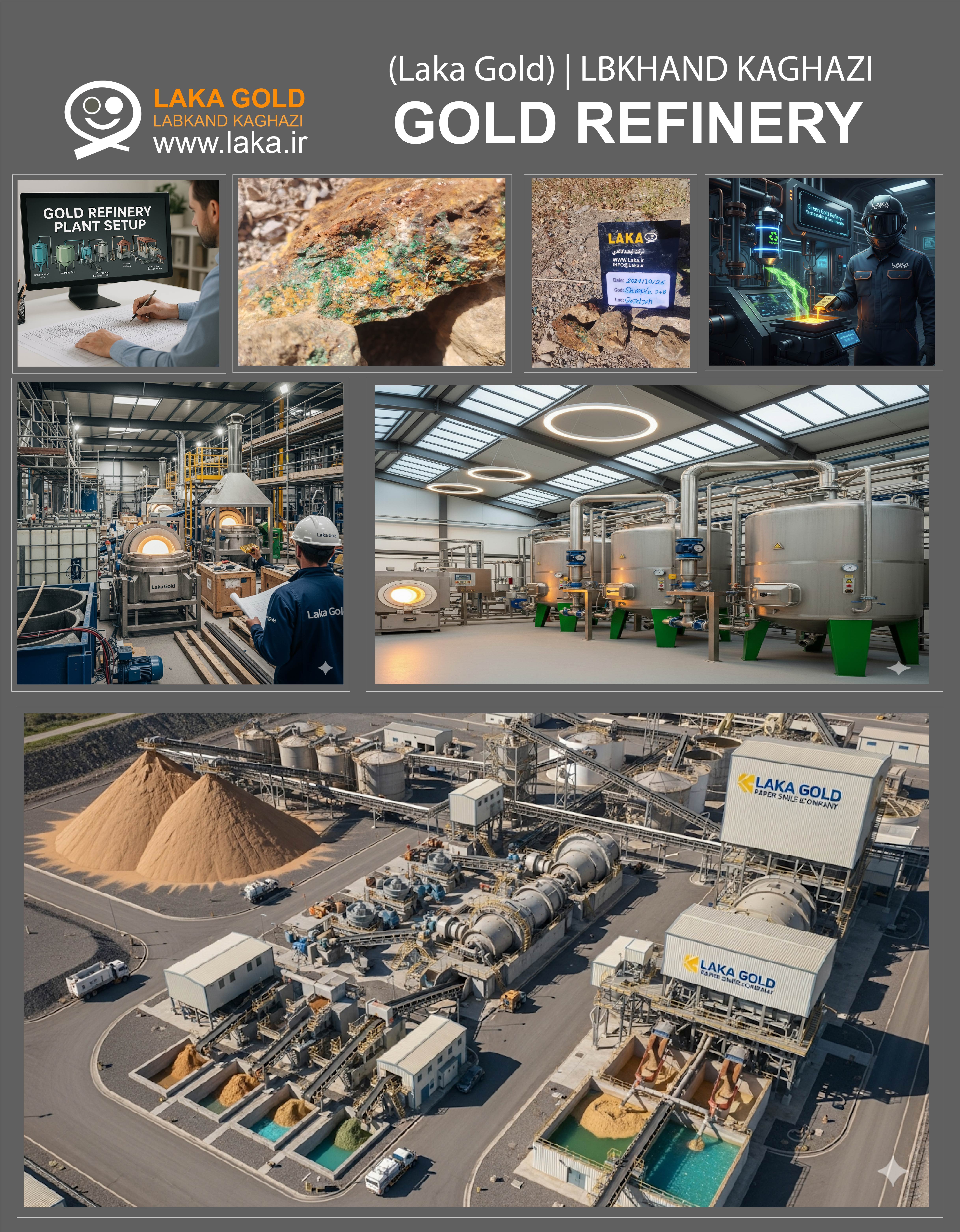

The Complete Guide to Gold Refining Plant Setup and Execution

Introduction to Gold Refining Plant Setup

Gold refining is a highly specialized industry, and setting up a gold refinery requires meticulous planning, a clear understanding of refining processes, advanced equipment, and compliance with legal regulations. A successful gold refinery setup involves several steps from concept and planning to equipment procurement and final operation.

This section explores each of the crucial steps involved in setting up a gold refinery and addresses common challenges encountered during the process. We’ll cover everything from initial feasibility studies to the detailed execution plan for a fully operational gold refinery plant.

1. Setting Up a Gold Refining Plant: Key Stages

Establishing a gold refinery plant involves key stages such as conceptual design, feasibility analysis, cost estimation, procurement of equipment, and regulatory approvals. Let’s break down each stage in more detail:

1.1 Initial Feasibility and Concept Design

The first stage in setting up a gold refining plant is conducting a feasibility study. This involves assessing the viability of the project based on gold supply availability, the refinery's capacity, expected purity levels, and the technology required.

- Site Selection: Choosing an appropriate site for the refinery is essential. Factors such as proximity to gold mining operations, environmental conditions, infrastructure (electricity, water supply), and proximity to transportation routes should be considered.

- Technology Selection: The selection of refining technology depends on factors such as ore type, scale of operation, and the desired purity level of the gold.

1.2 Equipment Procurement and Technology Choices

After the feasibility study, the next step is the procurement of equipment. The most common equipment used in gold refining includes:

- Crushers and Mills: For crushing and grinding gold-bearing ore to fine particles.

- Leaching Tanks: Used in cyanidation processes to extract gold from the ore.

- Electrolytic Cells: Used for electrorefining the gold.

- Smelting Furnaces: For melting the gold into dore bars.

- Gold Recovery Units: For recovering gold from cyanide solutions using activated carbon or other materials.

The choice of equipment depends on the scale of operations, whether small-scale, medium-scale, or large-scale refinery.

1.3 Design of the Gold Refining Plant Layout

A well-designed plant layout is essential to ensure smooth operations, safety, and efficiency. Some of the key design elements include:

- Separation of Hazardous Areas: Different areas of the plant must be designated for hazardous and non-hazardous operations, such as cyanide storage and smelting furnaces.

- Optimized Flow for Materials: The layout should ensure the most efficient flow of materials, from crushing to smelting and refining, minimizing the time and distance traveled by materials.

- Utilities and Support Systems: Proper design of water supply, air ventilation, and waste management systems is crucial.

2. Regulatory Compliance and Legal Approvals

Setting up a gold refinery also involves meeting the legal and regulatory requirements of the country where the plant is located. Some of the key regulatory steps include:

2.1 Obtaining the Necessary Permits

- Environmental Permits: Gold refining involves the use of chemicals such as cyanide, which can be hazardous to the environment. Refinery owners must obtain the necessary environmental permits that outline the safe disposal of chemicals and waste materials.

- Health and Safety Permits: Given the hazardous nature of refining processes, ensuring worker safety through proper permits and practices is critical. This includes safety gear, emergency response plans, and worker training.

- LBMA Certification: If the refinery plans to sell its refined gold in the international market, it must meet the standards set by the London Bullion Market Association (LBMA), which governs the purity and quality of refined gold.

2.2 Meeting Environmental and Social Standards

Gold refining plants must adhere to strict environmental and social standards, particularly regarding the use of toxic chemicals like cyanide and the management of hazardous waste. Some essential aspects include:

- Green Refining Technologies: Today’s industry standards demand sustainable and environmentally friendly refining practices. Green refining involves using alternative chemicals and technologies that reduce environmental harm, such as cyanide-free methods or closed-loop systems for waste.

- Social Impact Assessment: The refinery’s impact on the surrounding community, including issues like job creation and local infrastructure, must be assessed.

3. Operational Processes of a Gold Refining Plant

Once the plant is set up, operational processes must be well-defined. These processes ensure that gold is refined to the highest purity levels and that the refinery operates efficiently.

3.1 Gold Leaching and Separation Process

In the leaching process, gold ore is treated with cyanide solutions to dissolve the gold and separate it from other minerals. This solution is then treated with activated carbon or zinc to recover the gold.

- Cyanide Leaching Process: In this process, gold is dissolved in a cyanide solution. The gold-cyanide complex is then adsorbed by activated carbon or precipitated using zinc dust.

- Advantages: Cyanidation is effective for extracting gold from low-grade ores and has been the most widely used method for over a century.

3.2 Electrolytic Refining and Electrowinning

Electrolytic refining involves using electrolysis to separate gold from its impurities. A gold solution is passed through a cell where gold is plated onto a cathode.

- Gold Electrorefining: This process involves passing an electric current through a solution containing gold. The gold ions are reduced and deposited on the cathode, producing pure gold.

- Electrowinning: In this process, gold is recovered from solution by electrochemical means, typically from a cyanide leach solution.

3.3 Smelting and Gold Bar Production

Once gold is purified, it needs to be converted into solid bars for sale or further processing. The gold is melted in a smelting furnace and cast into gold bars.

- Smelting Furnace: The gold is heated to high temperatures in a furnace to melt it and separate it from other impurities. After melting, the gold is poured into molds to form bars or ingots.

- Gold Refining Bar Quality: The final purity of gold is typically 99.5% or higher, depending on the method used.

4. Gold Refining Cost Estimation and Economic Considerations

Setting up a gold refinery involves significant capital investment, with costs ranging based on the size of the plant and the technology used. Some of the main cost factors include:

- Initial Capital Costs: Includes land acquisition, equipment, building construction, and environmental compliance.

- Operational Costs: Costs associated with running the plant, such as labor, utilities (electricity, water), and raw material (gold ore).

- Maintenance and Replacement Costs: Regular maintenance of equipment is required, and parts need to be replaced over time to ensure smooth operations.

5. The Future of Gold Refining: Trends and Innovations

Gold refining is an evolving industry, with new technologies and sustainability practices shaping its future. Green refining techniques and technological innovations are pushing the boundaries of what is possible in refining.

- Innovation in Green Refining: New methods, such as cyanide-free gold extraction, are becoming more prominent. These methods minimize environmental impacts and increase sustainability.

- Automation and Efficiency: Automation of gold refining processes, such as robotic handling of materials and AI-based control systems, is improving efficiency and reducing costs.

Conclusion: The Importance of a Well-Executed Gold Refining Process

Setting up a gold refinery is a complex yet highly rewarding venture. By understanding the full process, from extraction to smelting, and ensuring proper plant design, equipment procurement, regulatory compliance, and sustainable practices, a successful and profitable gold refinery can be established.

The Complete Guide to Gold Refining Plant Setup and Execution (Continued)

6. Advanced Gold Refining Techniques and Innovations

As the gold refining industry continues to evolve, new techniques are constantly being introduced to improve efficiency, environmental sustainability, and cost-effectiveness. Here, we’ll explore some of the advanced refining techniques and innovations that are shaping the future of the industry.

6.1 Cyanide-Free Gold Refining Methods

One of the most promising innovations in gold refining is the development of cyanide-free refining methods. Traditionally, cyanide has been the most commonly used chemical for gold extraction, but due to its environmental and safety risks, alternative methods are being developed and adopted by many refineries worldwide.

-

Thiosulfate Leaching: This cyanide-free process uses thiosulfate as a lixiviant for gold extraction. Thiosulfate leaching is considered a greener option as it poses less environmental risk and can be more efficient in some ore types.

-

Aqua Regia Process: Aqua regia (a mixture of hydrochloric and nitric acid) can be used for gold dissolution, followed by precipitation methods to recover the gold. While this method is more effective in refining high-purity gold, it requires careful handling due to the corrosive nature of the acids.

-

Bioleaching: In bioleaching, bacteria are used to extract gold from ore, particularly in cases where traditional cyanidation might not be effective. This method is still in development but holds promise for a more sustainable gold refining process in the future.

6.2 Automation in Gold Refining Plants

Automation is becoming increasingly prevalent in the gold refining industry. It offers numerous benefits, including enhanced safety, improved precision, and reduced human labor costs.

-

Robotic Handling Systems: Robotics are being used to automate the transport of materials, from crushing and grinding to refining and smelting. This reduces the risk of human exposure to hazardous materials, such as cyanide.

-

Artificial Intelligence (AI) and Machine Learning: AI is playing a pivotal role in optimizing refining processes. AI-based systems can monitor plant conditions in real-time, predict failures, and optimize production schedules, ultimately improving plant efficiency and reducing downtime.

6.3 The Role of 3D Design and Virtual Prototyping

The use of 3D design software and virtual prototyping has revolutionized the planning and construction of gold refineries. These tools allow engineers to create highly detailed and accurate representations of refinery layouts before construction begins.

-

Virtual Plant Simulations: By simulating the entire refinery process in a virtual environment, designers can test different plant configurations, ensuring that materials flow efficiently and safely.

-

Digital Twin Technology: This technology involves creating a digital replica of the refinery in operation, which helps monitor real-time data for maintenance, performance optimization, and troubleshooting.

6.4 Future of Gold Smelting: Innovations in Furnace Design

The smelting furnace is a critical piece of equipment in the gold refining process. Innovations in furnace technology have led to improvements in energy efficiency, cost reduction, and better control over the smelting process.

-

Induction Furnaces: These electric furnaces are more energy-efficient than traditional gas furnaces and can achieve higher temperatures required for smelting gold. They also have the benefit of being environmentally cleaner.

-

Oxygen-Enriched Furnaces: These furnaces use oxygen to enhance combustion, thereby achieving higher temperatures more efficiently and reducing fuel consumption.

7. Financial Considerations for Gold Refining Plant Projects

Setting up a gold refinery is a capital-intensive project that requires careful financial planning. Below are some key financial aspects to consider when setting up a gold refinery:

7.1 Capital Investment Breakdown

The initial capital investment in a gold refinery includes several key components:

| Cost Component | Estimated Cost | Notes |

|---|---|---|

| Land Acquisition | $500,000 - $2,000,000 | Depends on location, proximity to mining operations, and size. |

| Construction Costs | $1,000,000 - $5,000,000 | Includes building the refinery structure, safety systems, etc. |

| Equipment Procurement | $2,000,000 - $10,000,000 | Depends on the scale of operations and technology used. |

| Environmental Compliance | $100,000 - $500,000 | Permits, waste management systems, and pollution control. |

| Regulatory Approval Fees | $50,000 - $200,000 | Fees for environmental, safety, and LBMA certification. |

7.2 Operational and Maintenance Costs

Once the refinery is operational, there are ongoing costs that need to be considered:

| Operational Costs | Estimated Annual Cost | Notes |

|---|---|---|

| Labor | $500,000 - $1,500,000 | Wages for skilled and unskilled workers. |

| Utility Costs (Electricity, Water, Gas) | $300,000 - $1,000,000 | Energy consumption is a significant operational cost. |

| Raw Material (Gold Ore) | $10,000,000+ | Dependent on the availability of gold-bearing ore and contracts. |

| Maintenance and Upkeep | $200,000 - $500,000 | Includes repairs, equipment upgrades, and replacement. |

7.3 Financial Returns and Profitability

The profitability of a gold refinery depends on factors such as gold prices, operational efficiency, and the quality of the refined gold produced. On average, a well-run refinery can expect to achieve a return on investment (ROI) within 3 to 5 years.

-

Gold Price Fluctuations: Gold prices are volatile, and fluctuations can significantly impact the profitability of the refinery. It's essential to monitor global gold prices and market trends closely.

-

Processing Capacity: Larger refineries with higher processing capacities can take advantage of economies of scale and reduce the per-ounce cost of refining.

8. Environmental Sustainability in Gold Refining

The gold refining industry is under increasing pressure to adopt sustainable practices. This is particularly important given the use of toxic chemicals such as cyanide in traditional refining processes.

8.1 Waste Management and Recycling

Gold refineries must have robust waste management systems to prevent contamination and ensure the safe disposal of harmful by-products, such as cyanide, acid, and smelting residues.

-

Closed-Loop Systems: These systems recycle water, chemicals, and metals, significantly reducing waste and environmental impact.

-

Recycling of Precious Metals: Refiners can also recycle other precious metals, such as silver and platinum, which are often present in gold ores.

8.2 Green Chemistry Innovations

The gold industry is increasingly focusing on the development of green chemistry solutions that reduce or eliminate the need for harmful chemicals in the refining process.

-

Cyanide-Free Leaching Technologies: As mentioned earlier, thiosulfate leaching is a promising green technology that is gaining traction as a safer alternative to cyanide-based processes.

-

Biotechnology and Bioleaching: The use of microorganisms to extract gold from ores is an eco-friendly method that is expected to become more widespread in the coming years.

Conclusion: Achieving Success in Gold Refining

Setting up and operating a successful gold refining plant is a complex but highly rewarding venture. With the right combination of feasibility studies, technological advancements, regulatory compliance, and sustainable practices, gold refining can be an environmentally responsible and profitable business.

By focusing on cutting-edge refining techniques, automation, and green technologies, the future of gold refining looks promising. The establishment of a well-planned gold refinery not only helps meet the growing demand for high-quality gold but also contributes to the economic development of the local community and the mining industry as a whole.

Web : www.laka.ir

Email : این آدرس ایمیل توسط spambots حفاظت می شود. برای دیدن شما نیاز به جاوا اسکریپت دارید

Tel : +985137665005

Catalog LAKA GOLD (Download PDF)