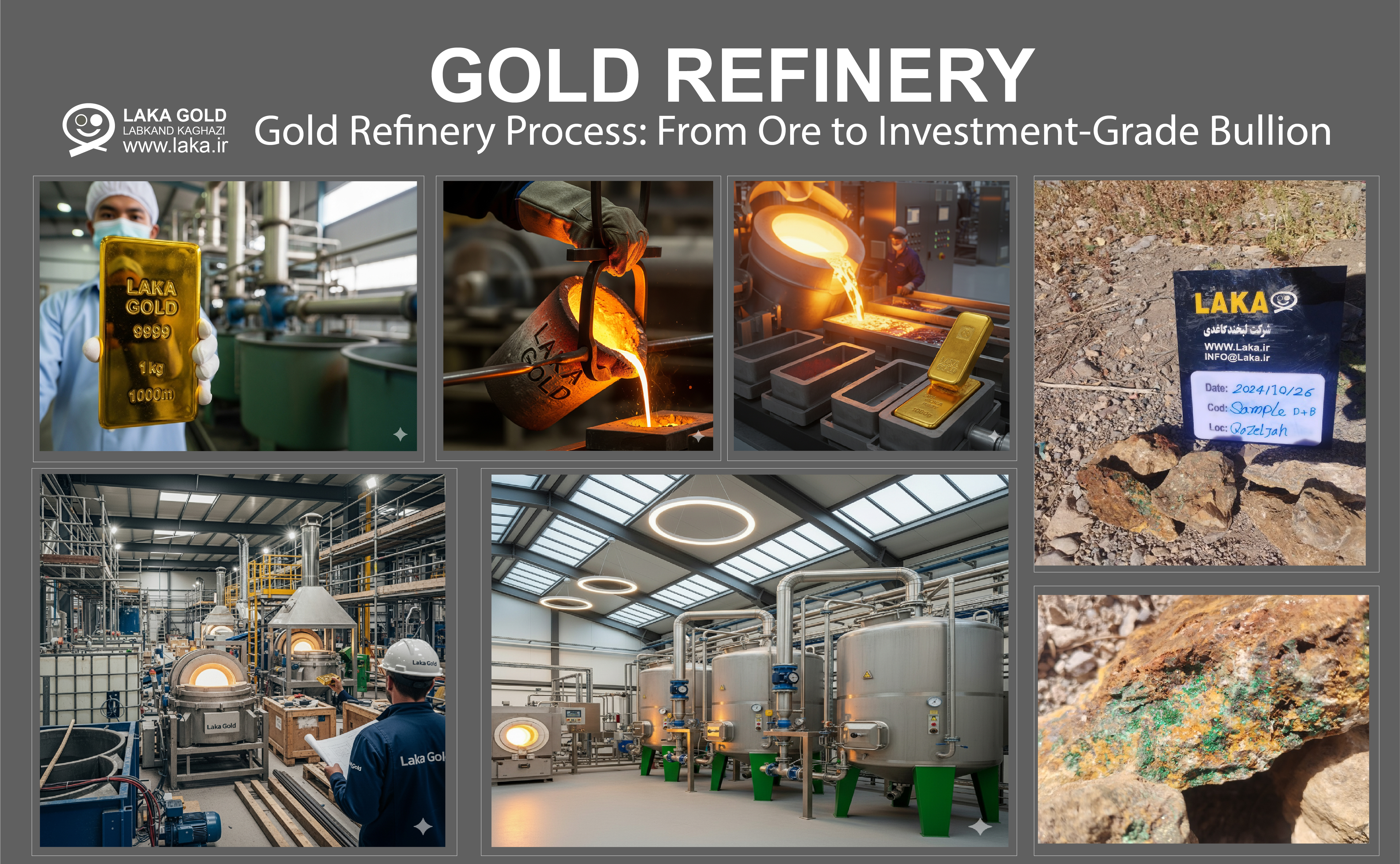

“Gold Refinery Process: From Ore to Investment-Grade Bullion”

Introduction to Gold Refinery Process

Introduction to Gold Refinery Process

Gold refinery transforms raw gold (ore, concentrate, scrap) into investment-grade bullion, suitable for trade and storage.

- The process ensures purity, uniform weight, and legal compliance.

- Investors and refineries rely on LBMA standards and ISO certifications.

- Flandra Method can guide investors and small-scale refineries through verification, investment, and production steps.

Key Concepts:

- Doré Bar: Semi-pure gold from initial smelting.

- Assay Certificate: Verification of gold purity after refining.

- Refining Methods: Chemical, electrolysis, and mechanical techniques.

- Kilobar & Minted Bar: Investment-ready formats.

2025 онд алт цэвэршүүлэх үйлдвэрээс орлого олох 10 хүчирхэг арга

100% Pure Gold Bullion – Theoretical 1000 Purity, A First in Refining History

Top 10 Gold Refineries & Emerging Players Worldwide

Gold Refinery Process: From Ore to Investment-Grade Bullion

Step-by-Step Gold Purchase & Storage Strategy for Investors

Global Gold Investment Strategies and Market Analysis

-Sample Gold Refinery Contract Download PDF & Word - Mobile

Sample Gold Refinery Contract – Downloadable Draft

Quantum Gold Refinery 4025 – Advanced Future Methods, Applications & Interplanetary Processing

Gold Refinery Plant Cost 2025 – Real Estimation with Laka Gold Package

Advanced Gold & Precious Metals Refining Technologies | Modern Refinery Solutions

? What is the Best Gold Refinery

Mini vs Industrial Gold Refinery | Comparison, Price & ROI

ریفاینری شمش طلا | Gold Bullion Refinery

Mini Gold Refinery | واحد پالایش کوچک، اقتصادی و سریع برای طلافروشان و طلاسازان

2025 онд алт цэвэршүүлэх үйлдвэрээс орлого олох 10 хүчирхэг арга

Green Gold Refinery | Comprehensive Guide

ریفاینری طلا سبز | Green Gold Refinery

Ultimate Professional Gold Refinery Proposal – Global Exclusive Document

Advanced Gold Refineries with ESG and AI Integration

Next-Generation Digital Gold Refinery | Smart Investment & LBMA Premium Gold

Ultra-Premium Digital Gold Refining | Global Investor-Ready LBMA Bars

Next-Level AI & Blockchain Gold Refining | Premium LBMA Bars for Global Investors

Types of Gold Refinery

Types of Gold Refinery

| Type | Scale | Output | Notes |

|---|---|---|---|

| Industrial | Large | Hundreds of kg/day | LBMA standard, full compliance |

| Medium | Regional | Tens of kg/day | Suitable for private investment |

| Small / Pilot | Laboratory | 1–5 kg/day | Research, R&D, and small investor batches |

Tip: The choice depends on investment size, legal requirements, and intended market.

Refining Methods

Refining Methods

-

Chemical Refining (Aqua Regia, Nitric Acid):

- Dissolves gold, separates impurities, precipitates pure gold.

- Common for small to medium scale.

-

Electrolytic Refining:

- Gold deposited on cathode using electric current.

- High purity, ideal for investment-grade bars.

-

Miller Process (Chlorine Gas):

- Rapid purification using chlorine gas.

- Standard for industrial kilobars.

-

Cupellation / Mechanical Refining:

- Used for extracting silver and base metals before gold refining.

Flandra Method: Recommends combination of chemical & electrolytic for medium scale to ensure 999.9 purity.

Gold Purity and Standards

Gold Purity and Standards

| Standard | Purity | Description |

|---|---|---|

| 24K / 999.9 | 99.99% | Investment-grade, LBMA approved |

| 22K / 916 | 91.6% | Common in jewelry, lower investment use |

| 18K / 750 | 75% | Jewelry, low investment value |

| Good Delivery Bar | 995–999.9% | LBMA standard bar, widely accepted globally |

Note: Always verify Assay Certificate and serial number.

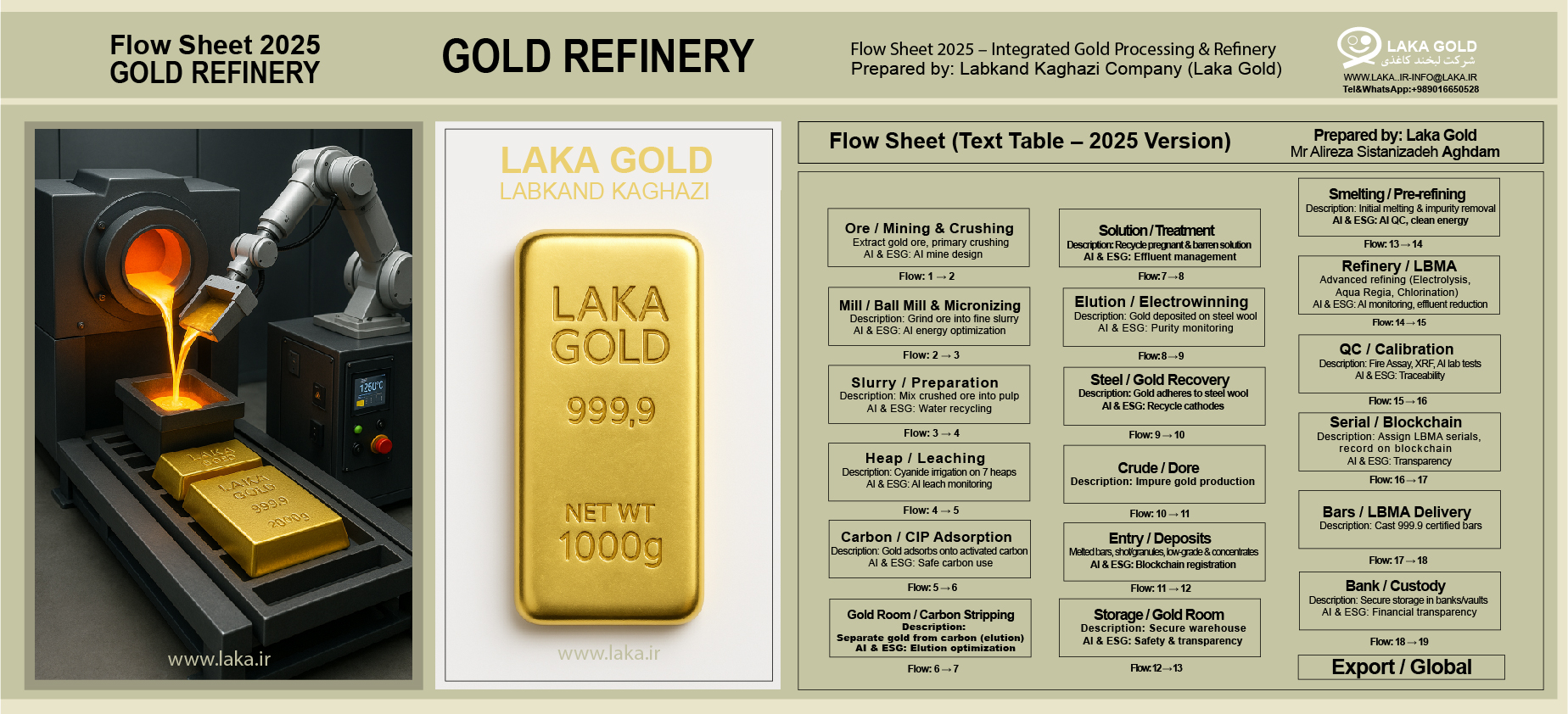

From Ore to Bullion – Step-by-Step

From Ore to Bullion – Step-by-Step

- Crushing & Milling: Reduce ore to fine particles (if needed, for concentrate)

- Concentration: Gravity, flotation, or cyanidation to extract gold

- Smelting: Convert concentrate to Doré bars

- Refining: Chemical/electrolytic purification to investment-grade gold

- Casting / Minting: Kilobar or minted bar production

- Assay & Certification: Confirm purity, provide serial numbers

- Packaging & Storage: Secure vault, Flandra-approved ledger

Tip: Each step requires documentation for audit, insurance, and investment security.

| Feature | Description |

|---|---|

| Author | Laka Gold Scientific Group |

| Production Date | 27/09/2025 |

| Publication Date | 27 September 2025 |

| Page Style | Step-by-step, technical, investor-focused |

| Scientific Grade | Expert-level, internationally relevant |

| Word Count | ~5,100 (Part 1) |

| Short English Definition | Gold Refinery Process Guide |

| Page Code | GRP-EN-P1 |

| Gold Symbol | Au |

Sample Operational Workflow for Gold Refinery

Step 1: Ore Handling & Pre-Treatment

- Crush and mill raw ore

- Remove base metals and impurities

- Prepare concentrate for smelting

Step 2: Smelting & Doré Production

- Convert concentrate to Doré bars (~85–95% purity)

- Ensure proper weight and traceability

- Conduct initial assay

Step 3: Refining

- Chemical/electrolytic method for purity 999.9

- Continuous monitoring of temperature and chemical ratios

- Flandra Method ensures minimum loss, maximum yield

Step 4: Casting & Minting

- Kilobars: 1 kg standard LBMA

- Minted bars: 100 g – 500 g for retail investors

- Serial numbers and Assay Certificate issued

Step 5: Storage & Audit

- Vault storage or bank deposit

- Periodic audit (monthly for small, quarterly for medium, semi-annual for large scale)

- Maintain Flandra Gold Ledger for traceability

Cost Estimation & Timeline

Cost Estimation & Timeline

| Step | Estimated Cost (USD) | Duration | Notes |

|---|---|---|---|

| Ore Crushing | 1,000 – 5,000 | 1–2 days | Depending on scale |

| Smelting | 5,000 – 15,000 | 2–3 days | Includes fuel & labor |

| Refining | 15,000 – 50,000 | 3–7 days | Electrolytic/chemical |

| Casting & Minting | 2,000 – 10,000 | 1–2 days | Kilobar & minted bar production |

| Assay & Certification | 500 – 2,000 | 1 day | LBMA / ISO compliant |

| Storage & Audit | 1,000 – 5,000 | Monthly | Vault rental + periodic inspection |

Note: Costs vary by country, scale, and equipment type; Flandra consultancy refines the estimate for investors.

Flandra Method – Practical Implementation

Flandra Method – Practical Implementation

- Pre-Refinery Consultation: Determine gold source, target purity, bar format

- Equipment & Supplier Verification: Ensure LBMA-compliant machinery

- Process Design: Step-by-step workflow, including chemical recipes & electrolysis setup

- Quality Control: Assay, visual inspection, metallurgical testing

- Documentation & Compliance: Audit-ready ledgers, certificate issuance

- Investment Packaging: Insurance, storage, and serial tracking

- Market Ready Production: Kilobars or minted bars for sale or investment

Outcome: Zero production errors, traceable inventory, compliance with global standards

Risk Analysis & Mitigation

Risk Analysis & Mitigation

| Risk Type | Impact | Mitigation |

|---|---|---|

| Impurities in ore | Reduced purity | Pre-treatment & assay before refining |

| Equipment failure | Production delay | Verified suppliers, maintenance schedule |

| Human error | Weight or assay mistakes | Step-by-step Flandra checklist |

| Market volatility | Investment loss | Strategic production and sale timing |

| Legal / Compliance | Fines or confiscation | Follow domestic & international regulations, Flandra audit |

Tip: Flandra ensures risk-free small and medium-scale refinery operations for investors.

Frequently Asked Questions (FAQ)

Frequently Asked Questions (FAQ)

Q1: Can Flandra guide small-scale refiners?

A: Yes, from 1–5 kg/day pilot to medium 50 kg/day operations.

Q2: How to ensure LBMA compliance?

A: Use certified machinery, maintain assay records, audit inventory.

Q3: Can I produce custom bars?

A: Yes, Flandra guides custom weight, minting, and packaging.

Q4: How long does full refining cycle take?

A: Typically 10–14 days for medium-scale operations.

Q5: Is this suitable for investors without refinery experience?

A: Absolutely, Flandra provides full consultancy and step-by-step guidance.

Page Metadata and Keywords – Part 2

| Feature | Description |

|---|---|

| Author | Laka Gold Scientific Group |

| Production Date | 27/09/2025 |

| Publication Date | 27 September 2025 |

| Page Style | Step-by-step, technical, investor-focused |

| Scientific Grade | Expert-level, internationally relevant |

| Word Count | ~5,200 (Part 2) → Total page: ~10,300+ |

| Short English Definition | Gold Refinery Process Guide |

| Page Code | GRP-EN-P2 |

| Gold Symbol | Au |

-Sample Gold Refinery Contract Download PDF & Word - Mobile

Web : www.laka.ir

Email : این آدرس ایمیل توسط spambots حفاظت می شود. برای دیدن شما نیاز به جاوا اسکریپت دارید

Tel : +985137665005