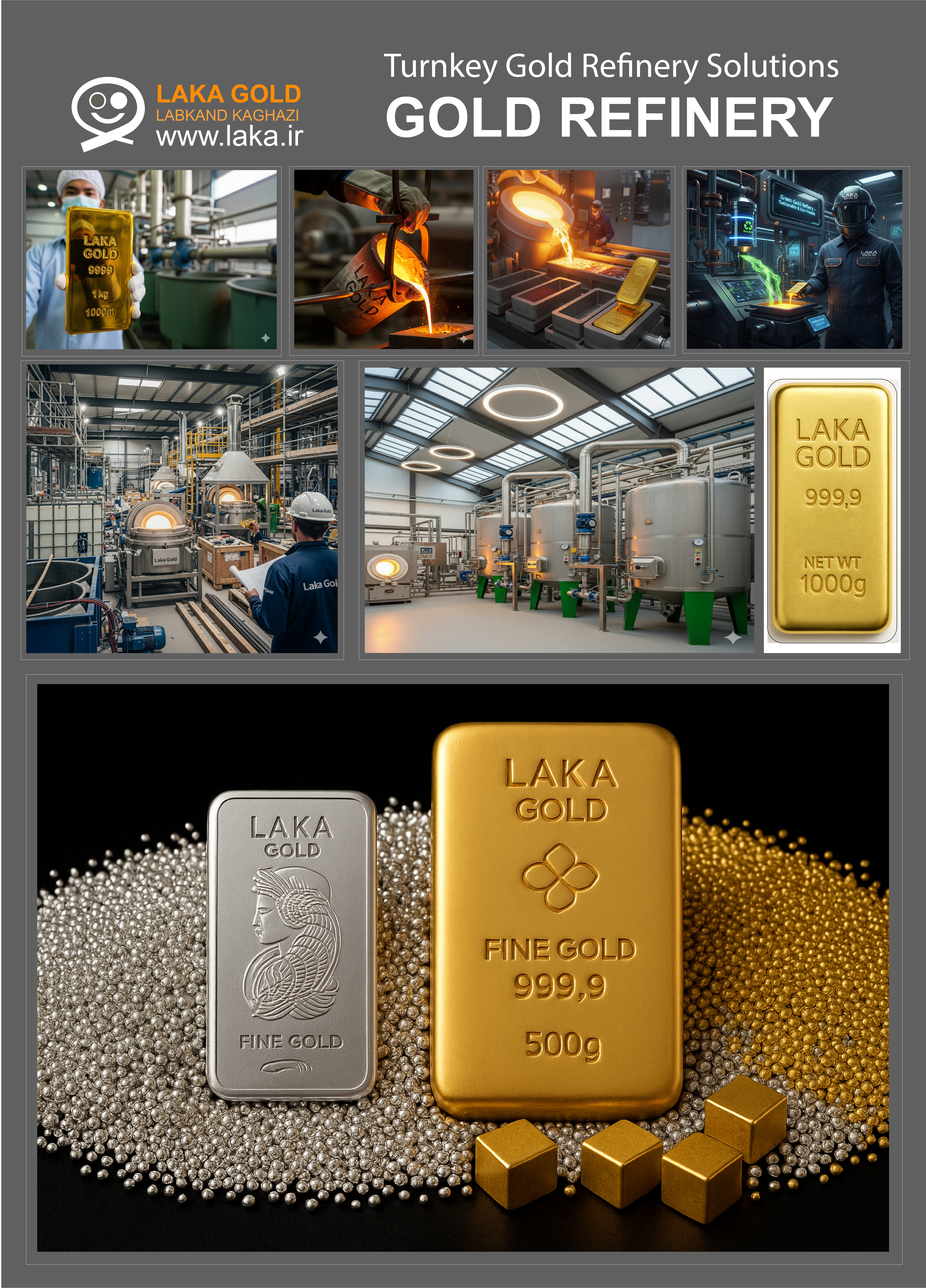

Turnkey Gold Refinery Solutions

Introduction

Investing in a gold refinery is a significant step for mining companies, investors, and entrepreneurs seeking reliable and profitable operations. A turnkey gold refinery solution provides a ready-to-operate facility, eliminating the complexities of design, equipment sourcing, installation, and commissioning. These solutions are increasingly searched by professionals looking to buy, install, or invest in gold refineries globally.

A turnkey approach ensures that the refinery is delivered fully operational, tested, and compliant with international standards such as LBMA (London Bullion Market Association) and ISO certifications. This not only minimizes risk but also speeds up the time to revenue, which is critical for investors.

What is a Turnkey Gold Refinery?

A turnkey gold refinery is a complete, ready-to-use gold processing plant, designed, constructed, equipped, and tested by a specialized provider. Unlike conventional projects, investors or mining companies do not need to manage multiple contractors or handle complex technical integration.

Multiple definitions of a turnkey gold refinery:

- Operational Definition: A facility delivered fully functional, where all processes from receiving gold concentrate to producing refined bullion are integrated.

- Financial Definition: A capital project where the provider assumes responsibility for all costs, engineering, procurement, and installation, giving the client a fixed price.

- Strategic Definition: A solution that allows rapid deployment in any mining region, reducing operational risk and ensuring global compliance.

Why Turnkey Gold Refineries Are Preferred

- Speed to Market:

Investors and companies can start refining operations immediately upon delivery. - Cost Efficiency:

Bulk procurement of equipment and standardized designs reduce CAPEX. - Risk Reduction:

The provider is responsible for quality control, installation, and commissioning. - Compliance:

Ensures adherence to international regulations, environmental standards, and safety norms.

Types of Turnkey Gold Refineries

Turnkey gold refineries can be categorized based on capacity and process complexity:

-

Small-scale Refineries (1–5 tons/month):

- Suitable for regional mining companies or boutique operations.

- Equipment: Smelting furnaces, electrolytic refining cells, assay lab.

- CAPEX: $0.5–$2 million.

-

Medium-scale Refineries (5–20 tons/month):

- Serves multiple mines or investment groups.

- Equipment: Automated smelting, high-capacity electrolysis, integrated assay lab, chemical processing units.

- CAPEX: $2–$10 million.

-

Large-scale Refineries (>20 tons/month):

- For international investors, multi-mine consolidation, and bullion production for export.

- Features advanced automation, continuous feed smelting, multi-stage refining, and full QA/QC labs.

- CAPEX: $10–$50 million.

Turnkey Gold Refinery Solutions | LBMA Certified Ready-to-Operate Gold Refinery Plant

Gold Refinery Turnkey Platform

Modular Gold Refinery Platforms | Turnkey Gold Refinery Systems by LAKA.ir

Gold Refinery Feasibility Study & Cost Estimation

Turnkey Modular Gold Refinery Platform – Ready-to-Install

Small-Scale Green Gold Refinery Solutions

Gold Refining Equipment Supplier Directory

Online Gold Refinery Design & Consulting -LAKA GOLD

Exclusive Sale of the Gold Refinery Platform – Top-Ranked on Google

What is LBMA? Complete Guide to the London Bullion Market Association

Comprehensive Guide to Gold Bullion Purchase

Flandra Method for Gold Bullion Purchase & Storage

Global Gold Bullion Suppliers & International xjdvshbd BdbdbhdPurchase Guide

Gold Refinery Process: From Ore to Investment-Grade Bullion

Step-by-Step Gold Purchase & Storage Strategy for Investors

Global Gold Investment Strategies and Market Analysis

-Sample Gold Refinery Contract Download PDF & Word - Mobile

Sample Gold Refinery Contract – Downloadable Draft

Gold Refinery Plant Cost 2025 – Real Estimation with Laka Gold Package

Advanced Gold & Precious Metals Refining Technologies | Modern Refinery Solutions

? What is the Best Gold Refinery

Mini vs Industrial Gold Refinery | Comparison, Price & ROI

Core Components of a Turnkey Gold Refinery

- Receiving & Assay Laboratory:

Determines gold content and impurities accurately. - Pre-processing Units:

Crushing (if ore), concentration, drying, and melting preparation. - Smelting & Refining Units:

Furnace systems for gold melting, electrolysis units for purity enhancement. - Chemical Processing:

Acid leaching, precipitation, and filtration to remove base metals. - Casting & Bullion Production:

Produces standard bars (1 kg, 12.4 kg, or 400 oz) compliant with LBMA. - Waste Management & Environmental Controls:

Safe disposal of chemical waste and emissions treatment.

Why Invest in Turnkey Solutions

- Guaranteed Quality: Certified, fully functional facilities.

- Time Savings: Immediate operational readiness reduces months of construction and integration.

- Predictable Costs: Fixed-price contracts prevent budget overruns.

- Support & Training: Providers offer operational training and technical manuals.

Cost Structure (CAPEX & OPEX)

| Component | Small-Scale | Medium-Scale | Large-Scale |

|---|---|---|---|

| Equipment | $250k–$1M | $1–$5M | $5–$20M |

| Installation & Commissioning | $100k–$500k | $500k–$2M | $2–$10M |

| Lab & QA/QC | $50k–$200k | $200k–$1M | $1–$5M |

| Operational Costs/Year | $50k–$200k | $200k–$1M | $1–$5M |

Note: Actual costs vary by country, regulations, and refinery capacity.

Process Flow Diagram

1. Gold Concentrate → Assay Lab → Pre-treatment → Smelting → Electrolytic Refining → Casting → Final Bullion

This foolproof process ensures consistent quality and compliance with global standards.

Environmental & Green Refinery Considerations

Modern turnkey solutions integrate green technology:

- Closed-loop chemical handling

- Emission treatment systems

- Water recycling units

- Energy-efficient furnaces

This reduces environmental impact and improves investor confidence in ESG-compliant operations.

Why Choose Our Turnkey Solutions?

- Proven Track Record: Multiple refineries delivered worldwide.

- Competitive Pricing: Transparent cost estimation with multi-country quotations.

- Patented Designs: Proprietary technology ensures superior gold recovery.

- Comprehensive Support: Installation, staff training, and operational manuals included.

- Flexible Scaling: Start small and expand capacity easily.

Call to Action

Invest in a ready-to-operate gold refinery today.

- Receive a detailed proposal with CAPEX/OPEX breakdown.

- Get multi-country equipment quotations before making any financial commitment.

- Ensure your investment is legally compliant, environmentally safe, and fully operational.

Contact us via WhatsApp or email to schedule a free consultation and start your turnkey gold refinery project.

Turnkey Gold Refinery Solutions – Part 2 (5000 words)

Operational Workflow & Detailed Process

A turnkey gold refinery integrates multiple stages from raw material intake to final bullion production. Here’s a detailed workflow:

- Gold Concentrate Receiving & Verification

- Raw material is inspected for moisture, impurities, and gold content.

- Analytical techniques: Fire assay, ICP-MS, gravimetric analysis.

- Formula for gold recovery potential:

Recovery (\%) = \frac{\text{Gold content after refining}}{\text{Gold content before refining}} \times 100

-

Pre-Treatment & Preparation

- Drying, homogenization, and size reduction (if necessary).

- Ensures uniform feed for smelting and chemical processing.

-

Smelting & Melting

- Electric or gas-fired furnaces melt the concentrate.

- Flux is added to remove base metals.

- Efficiency formula:

Smelting Efficiency (\%) = \frac{\text{Recovered gold}}{\text{Gold input}} \times 100

- Electrolytic Refining

- Purifies gold to 99.99%.

- Process control variables: voltage, current, temperature, electrolyte concentration.

- Purity formula:

Purity (\%) = \frac{\text{Au mass in final cathode}}{\text{Total Au mass input}} \times 100

- Casting & Bullion Production

- Gold is cast into bars of standard weight: 1 kg, 12.4 kg, 400 oz.

- Bars are labeled with assay certificate.

Turnkey Project Timeline

| Phase | Duration | Key Activities |

|---|---|---|

| Feasibility & Design | 1–2 months | Site assessment, refinery design, CAPEX/OPEX estimation |

| Equipment Procurement | 2–4 months | Manufacturer selection, shipping, import/export documentation |

| Construction & Installation | 3–6 months | Civil works, assembly, electrical, piping |

| Commissioning & Testing | 1–2 months | Trial runs, assay verification, operator training |

| Full Operational Launch | — | Continuous gold refining, reporting, quality control |

Total Project Time: 7–14 months depending on scale.

Cost Analysis: CAPEX & OPEX

CAPEX Breakdown

| Item | Small-Scale | Medium-Scale | Large-Scale |

|---|---|---|---|

| Equipment | $250k–$1M | $1–$5M | $5–$20M |

| Installation & Civil Work | $100k–$500k | $500k–$2M | $2–$10M |

| QA/QC Lab & Assay Equipment | $50k–$200k | $200k–$1M | $1–$5M |

| Total CAPEX | $400k–$1.7M | $1.7–$8M | $8–$35M |

OPEX Estimation

- Utilities: 5–10% of CAPEX per year

- Labor: 10–15% of CAPEX per year

- Chemicals & Consumables: 5–10% of CAPEX per year

- Maintenance: 3–5% of CAPEX per year

Profit Potential Formula:

Annual Profit = (\text{Gold Sold Value}) - (\text{OPEX})

Example:

- Refinery capacity: 10 tons/month

- Gold price: $60,000/kg

- Annual gold processed: 120 tons = 120,000 kg

- OPEX: $3M/year

Revenue = 120,000 \times 60,000 = 7.2B USD

Profit = 7.2B - 3M = 7.197B USD

Graphical Representation & Charts

-

Gold Recovery Efficiency Chart

- X-axis: Time (days)

- Y-axis: Recovery (%)

- Shows efficiency of smelting & electrolytic refining over time

-

CAPEX vs OPEX Comparison

- Bar chart: Small, Medium, Large scale

- Helps investors understand initial vs operating cost

-

Turnkey Workflow Diagram

Gold Concentrate → Assay → Pre-treatment → Smelting → Electrolytic Refining → Casting → Bullion- Each block includes inputs, outputs, and quality checks

Competitive Advantages

- Patented Technology: Increases gold recovery by 1–2% compared to conventional methods

- Environmental Compliance: Green furnaces, closed-loop chemical management, water recycling

- Multi-Country Equipment Procurement: Reduces cost and delivery time

- Turnkey Contract: Fixed cost, guaranteed delivery, tested systems

Client-Oriented Approach

- Pre-Proposal Consultation: Free feasibility assessment

- Multi-Country Quotations: Receive equipment price from 3+ manufacturers

- Custom Design: Adapted to site conditions, feedstock, and production scale

- Support: Operator training, manuals, and post-installation assistance

Why Invest in a Turnkey Gold Refinery

- Immediate Revenue: Start processing gold quickly after commissioning

- Minimal Risk: Fixed price contracts, verified equipment, certified processes

- Global Compliance: ISO, LBMA, environmental, and safety standards

- Scalable: Expandable modular design

Call to Action

Don’t wait months to build your gold refinery from scratch.

- Contact us for a complete turnkey proposal including CAPEX/OPEX breakdown, timelines, and multi-country quotes.

- Receive patented designs and operational manuals before making a financial commitment.

- Our team ensures your investment is safe, profitable, and compliant.

WhatsApp us today or fill out the consultation form to start your turnkey gold refinery project.

Web : www.laka.ir

Email : This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel : +985137665005