Gold Refining: Its Importance and Role in Global Trade – PART ONE

(Introduction)

Gold refining is one of the most critical strategic industries in the modern world. It intersects advanced technology, global economics, and precious metals trade, forming a cornerstone of international commerce. Gold, for thousands of years, has been more than a precious metal; it serves as a store of value, a medium of trust, and a financial instrument relied upon by nations, central banks, and investors during economic volatility. As global markets have evolved, ensuring the purity and quality of gold has become essential. Consequently, refining is no longer a simple metallurgical process but a standard for distinguishing low-grade or raw gold from high-purity, globally accepted bullion.

Refining encompasses a comprehensive system of chemical, physical, and operational procedures designed to separate gold from impurities such as silver, copper, platinum, and palladium. The proportion of these associated metals varies depending on the geographic source of the raw material, necessitating specialized processing techniques tailored to the composition of the gold feedstock. Technological advancements have introduced methods including electrolytic refining, precise chemical reactions, precipitation, and separation processes, enabling the achievement of 99.99% pure gold with reliability and efficiency.

Globally, gold refined to meet LBMA (London Bullion Market Association) standards represents the accepted benchmark for international trade. Central banks, sovereign funds, and investment institutions will only transact with certified refined gold. Therefore, refining today is not merely production; it is a global trust certification. Compliance with internationally recognized refining standards ensures that bullion can circulate in financial markets, serve as collateral, and meet investment-grade requirements.

Dubai has emerged as a central hub in this domain over the past two decades, evolving from a regional trading post into one of the most influential global centers for gold commerce. Its strategic location between Asia, Africa, and Europe, along with a robust infrastructure, modern free zones, and investment-friendly regulations, has attracted numerous investors to establish gold refineries. Understanding the definition of gold refining and its role in global trade allows investors and policymakers to assess the significance of entering this high-value sector.

The refining process involves multiple stages beyond simple smelting. Initial separation targets associated metals and impurities present in doré bars, recycled jewelry, electronic scrap, or mining concentrates. Chemical methods include aqua regia (a mixture of nitric and hydrochloric acids), electrolytic refining, chlorine-based Miller processes, and advanced organic solvent extraction techniques. Each method offers advantages depending on the raw material quality, desired throughput, operational cost, and purity requirements.

Once the gold reaches the required purity level, it is cast into bars or ingots of various sizes—from one gram to 12.5 kilograms. Each bar is stamped with the refinery’s hallmark, batch number, production date, and purity level, forming an internationally recognized certification. Analytical techniques such as X-ray fluorescence (XRF), fire assay, and spectroscopic methods verify compliance with stringent international standards, allowing the refined gold to enter the global bullion market.

Dubai’s strategic position facilitates not only the technical aspects of refining but also operational and commercial advantages. Free zones such as DMCC, JAFZA, and DAFZA provide tax exemptions, streamlined licensing, and customs-free storage. These zones enable refiners to import raw materials, operate high-security facilities, and export certified gold efficiently. With the combination of robust infrastructure, regulatory clarity, and strategic logistics, Dubai has attracted leading regional and international refining companies seeking secure, high-volume operations.

Refining is also vital for environmental and regulatory compliance. Modern refineries implement emission controls, recycle chemical reagents, treat wastewater, and adopt energy-efficient technologies. These measures mitigate environmental impact while ensuring adherence to ISO and LBMA standards. Furthermore, certified refining provides traceability that helps prevent illicit gold trading, money laundering, and unauthorized cross-border transfers, reinforcing Dubai’s reputation as a trusted global bullion hub.

Economically, gold refining transforms low-value raw materials into investment-grade products, generating high added value. Companies can diversify revenue streams through refining services, customized bullion production, and precious-metal logistics. The industry supports employment, stimulates ancillary sectors such as assaying laboratories and precious-metal trading services, and contributes to national and regional GDP.

In conclusion, gold refining is a sophisticated, multi-dimensional industry that combines chemistry, metallurgy, quality control, regulatory compliance, and economic strategy. Dubai, by providing a secure, tax-advantaged, and globally connected environment, exemplifies the ideal setting for refining operations. Understanding the critical importance of refining in global trade empowers investors and policymakers to make informed decisions in this rapidly growing, high-value industry.

Comprehensive introduction to gold refining and its importance in global trade.

How to Establish a Gold Refinery in Free Zones of Dubai

The Importance of LBMA Certification in the Gold Refining Industry

Invest in Gold Refining — Exceptional Profits & Strategic Asset-Backed Growth

Gold Refinery Project & Investment Opportunities

Gold Refinery Layouts | 500m² Facility Design, Equipment Placement, and Operational Planning

Gold Refinery Business Plan & Feasibility Guide 2025

Gold Refinery Patent Reference

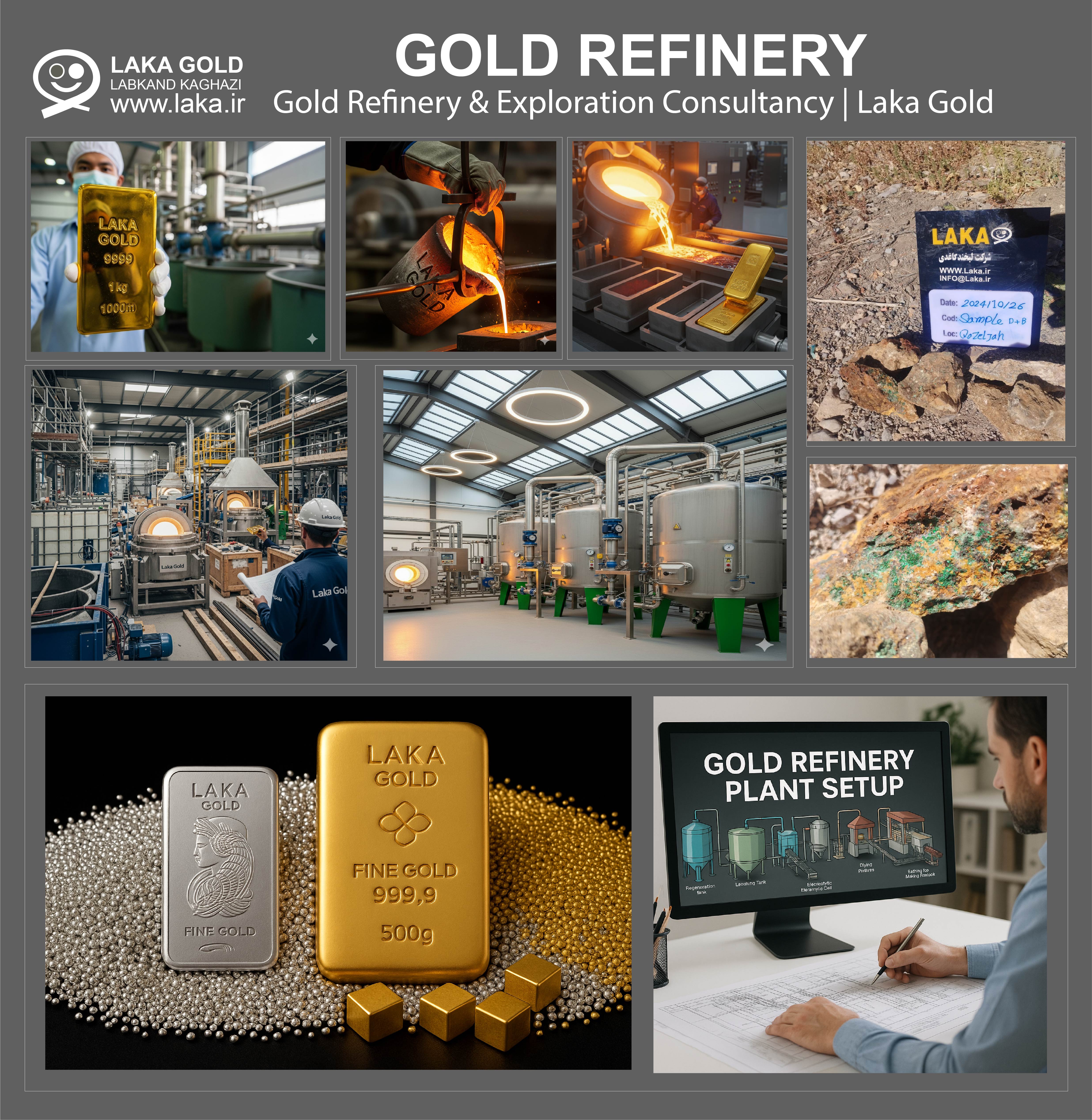

Laka Gold (Labkhand Kaghazi) | From Exploration to Gold Refinery & Mining Services

Modular Gold Refinery Platforms | Turnkey Gold Refinery Systems by LAKA.ir

Exclusive Sale of the Gold Refinery Platform – Top-Ranked on Google

Online Gold Refinery Design & Consulting -LAKA GOLD

Gold Refining Equipment Supplier Directory

Modular Gold Refinery Platforms | Turnkey Gold Refinery Systems by LAKA.ir

What is LBMA? Complete Guide to the London Bullion Market Association

Comprehensive Guide to Gold Bullion Purchase

Step-by-Step Gold Purchase & Storage Strategy for Investors

-Sample Gold Refinery Contract Download PDF & Word - Mobile

Quantum Gold Refinery 4025 – Advanced Future Methods, Applications & Interplanetary Processing

Mini vs Industrial Gold Refinery | Comparison, Price & ROI

"Gold Mine for Sale | Gold Mining Partnership & Supply Services - Laka Gold"

Global Sample Mini Gold Refinery | Compact, Scientific & Economical Gold Refining Unit

Compact Mini Gold Refinery for Workshops & Shops | Scientific & Economical Gold Refining Unit

Next-Generation Digital Gold Refinery | Smart Investment & LBMA Premium Gold

Gold Refining: Detailed Process and Industry Insights – PART TWO (English)

Introduction to Gold Refining Processes

Gold refining is a complex, multi-stage process that transforms raw or low-purity gold into high-purity bullion suitable for international trade, investment, and industrial applications. This stage of refining involves a meticulous sequence of chemical, physical, and metallurgical procedures designed to remove impurities such as silver, copper, platinum, palladium, and trace metals. Modern refining is guided by both scientific precision and regulatory compliance, ensuring that refined gold meets the highest standards, such as those set by the London Bullion Market Association (LBMA).

Refining begins with the reception and classification of gold feedstock. Sources may include mined doré, scrap gold from jewelry, industrial residues, and recycled electronic components. Each type of input has a unique composition that dictates the specific refining pathway. Modern refineries employ advanced analytical techniques, including X-ray fluorescence (XRF), fire assay, and inductively coupled plasma optical emission spectrometry (ICP-OES), to determine the precise content of gold and associated metals.

Stage 1: Material Reception and Preprocessing

Upon arrival at the refinery, gold-bearing materials are carefully sorted and weighed. Quality control laboratories verify the composition, detecting contaminants and assessing the preliminary purity. Preprocessing may involve mechanical separation to remove non-metallic impurities, followed by preliminary smelting to consolidate the gold content into a manageable form.

Stage 2: Primary Smelting

The gold is then subjected to high-temperature smelting in specialized furnaces, reaching temperatures exceeding 1100°C. Fluxes, such as borax and soda ash, are added to bind with slag-forming impurities, allowing their separation from molten gold. This stage eliminates a significant proportion of base metals and non-metallic contaminants, producing a partially refined product ready for chemical treatment.

Stage 3: Chemical Refining Techniques

Chemical refining transforms the partially purified gold into investment-grade bullion. The principal methods include:

-

Aqua Regia Refining

- Gold is dissolved in a mixture of nitric and hydrochloric acids.

- Impurities form insoluble residues, while gold remains in solution.

- Gold is precipitated using reducing agents such as ferrous sulfate or sulfur dioxide.

- This method achieves purity levels exceeding 99.9% and is widely used in jewelry and industrial applications.

-

Electrolytic Refining

- Molten or solution-phase gold undergoes electrolysis.

- Gold ions migrate to the cathode, depositing as high-purity crystals.

- This method produces gold with purity up to 99.99%, suitable for bullion trading and LBMA certification.

-

Miller Chlorination Process

- Molten gold is treated with chlorine gas, converting base metals into chlorides.

- The remaining gold reaches high purity and can be cast into bars.

- This process is suitable for high-volume industrial production due to its speed and efficiency.

-

Organic Solvent Extraction

- Innovative techniques use organic reagents to selectively dissolve gold from electronic scrap or complex ores.

- These methods are increasingly important for recycling e-waste and secondary gold recovery.

Stage 4: Casting and Assaying

Once chemical purification is complete, gold is cast into ingots or bars of varying sizes, from 1 gram to 12.5 kilograms. Each bar is stamped with the refinery’s hallmark, batch number, production date, and gold purity. Assaying laboratories perform verification using XRF, fire assay, and spectrometry, ensuring compliance with international standards. Certified bars are then eligible for trading in global markets.

Stage 5: Quality Control and Certification

Refineries implement strict quality control to maintain LBMA compliance. This includes traceability from source to finished product, verification of supply chain due diligence, anti-money laundering (AML) procedures, and adherence to environmental standards such as ISO 14001. Certifications provide investors, central banks, and trading houses confidence in the legitimacy and purity of the bullion.

Website: laka.ir

Email: این آدرس ایمیل توسط spambots حفاظت می شود. برای دیدن شما نیاز به جاوا اسکریپت دارید

WhatsApp/Phone: +98-901-665-0528

Tel : +985137665005

Management:Mr. Alireza Sistanizadeh Aghdam

Catalog LAKA GOLD (Download PDF)

-Sample Gold Refinery Contract Download PDF & Word - Mobile

EXCLUSIVE SALE OF THE GOLD REFINERY PLATFORM – TOP-RANKED ON GOOGLE

“Gold Refinery & Polymetallic Exploration Consulting — From Rock to Bullion”